- T-MAX Products

- Aluminum Raw Material Silos

- Blendmax Multi-flow Blending Bins

Blendmax Multi-Flow Blending Silos

•Plastics must be homogenously mixed before entering the process or packaging machine immediately after production.

•For this purpose, t-max Multi-Stream Mixing Silo Technology is used.

•Today, many companies use horizontal or vertical mechanical mixers to ensure homogeneous mixing during plastic production.

•However, some problems are encountered when using these types of mixers.

FEATURES

•Unnecessary time loss occurs during raw material changes.

•There is difficulty in cleaning the silo interior and limited intervention areas.

•Increased dust levels due to friction can be problematic.

•Unwanted crushing and shape distortions can occur in the structure of the granules.

•Excessive friction can cause granules to heat up, leading to surface damage.

•Sudden and long-term failures can occur due to mechanical or bearing sources.

•Bearing or bronze bushings require regular lubrication, and if not done, there is a risk of oil dripping onto the raw material.

•Helical blades used in glass fiber reinforced production can cause constant need for spare parts due to wear or inner tube abrasions.

•Since the helical blades work continuously, there is a risk of breakage and damage due to metal fatigue.

•There is a risk of contamination within the raw material.

•Long maintenance times and high maintenance costs occur.

•t-max has developed the “Multi-Stream Silo” technology to overcome these and similar issues to ensure continuous production efficiency.

•t-max has solved all problems by using the gravity mixing method and conical inner structure design.

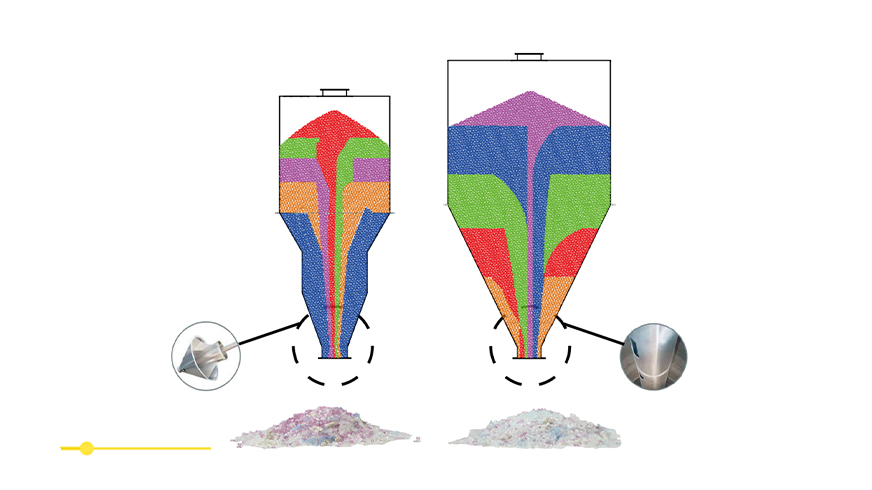

•Depending on the characteristics and structure of the raw material, different gravity mixing methods are preferred.

•The visual below shows some factors that play a role in these preferences.

•t-max expert engineers will recommend the most suitable design for your operation based on the tests they perform depending on the structure and variety of the raw material.

•To test your raw material, we will determine the appropriate silo volume and mixing method to be applied using the methods we will use at our test center located in our existing silo factory.

FEATURES

•t-max offers a wide range of silos from 1 m³ to 250 m³.

•Provides fast, excellent, and continuous homogeneous mixing.

•Since no helical blades are used, very fast cleaning can be performed in conical or cylindrical body windows.

•Quick and easy lower cone replacement can be done in materials with a high risk of wear thanks to flanged connections.

•t-max silos are known for their dust-free and damage-free structure.

•There are zero maintenance costs with its maintenance-free design.

•Completely eliminates known and experienced mechanical mixer problems.

•Offers flexibility for both continuous and batch operation.

•Can be easily applied to new or existing silos.

•Has a unique structure and design in terms of occupational safety.

To receive more detailed technical information about the product, please fill out the form below.