- T-MAX Products

- Bagomax Automatic Bag Opening / Emptying

- Semi-Automatic Bag Opening and Emptying

Bagomax Semi-Automatic Bag Opening and Emptying Machine

FEATURES

- The emptying capacity is determined as 5-8 tons per hour.

- The emptying capacity can vary depending on the raw material and packaging material.

- Standard 25 kg plastic granule bags are fed to the conveyor by the operator.

- After the opened conveyor, the bags are cut with rotary blades on the flat conveyor.

- Raw materials are poured into the specially designed cylindrical sieve, ensuring easy and complete emptying into the hopper.

- The emptying efficiency is higher than 99.98%.

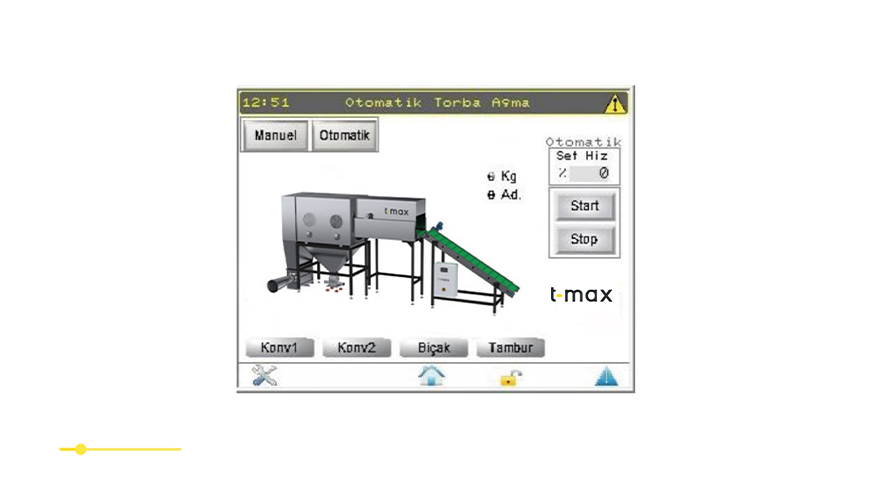

- The machine control is provided with a 12-inch touch color control screen.

- The conveyor feed rate can be adjusted.

- There are emergency stop buttons around the machine.

- Surfaces in contact with raw materials are made of AISI 304 stainless steel.

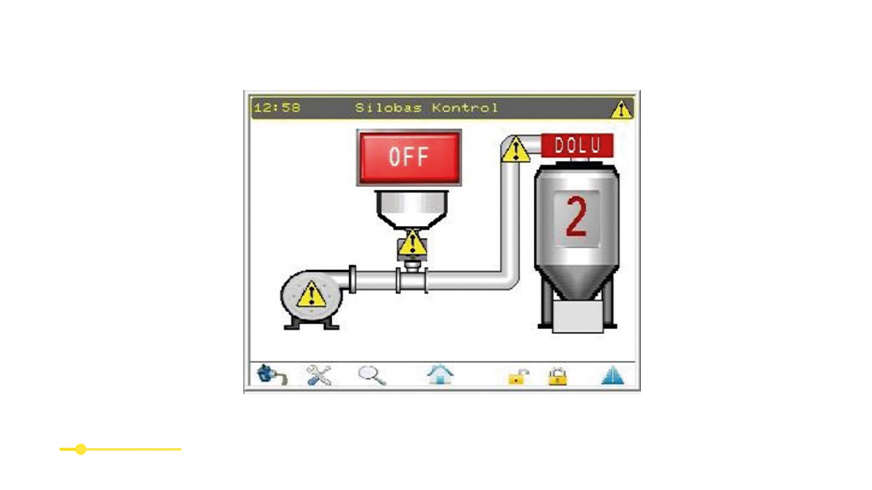

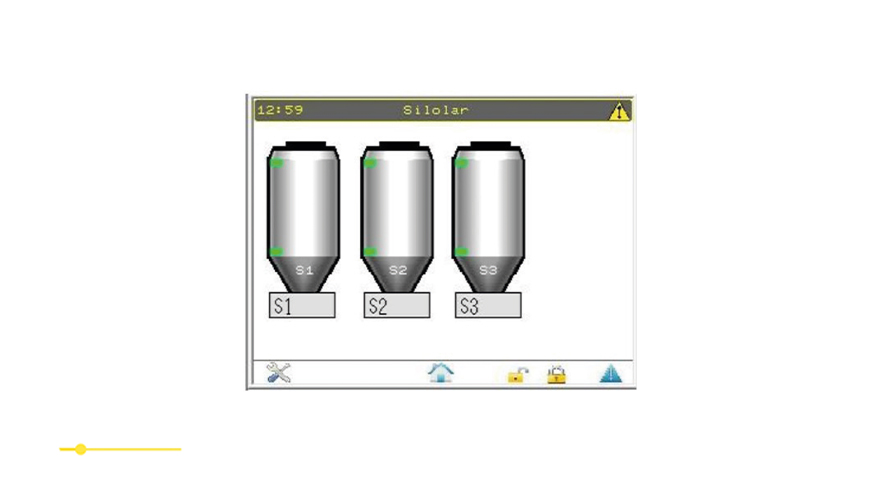

- There is an automation system that stops the conveyor when the hopper is full.

- The machine has a fast and easy setup.

- It has a compact design.

Options

Bag Compactor (empty bag compactor)

- The cut bags are compacted by a helical bag compactor within the sieve.

- Thanks to its powerful gear motor, the machine runs smoothly and has a long lifespan.

- It compacts waste bags into PE sausage bags, reducing their original volume by approximately 8 times.

- The machine can compact different bag materials such as original PE, paper, PE-coated paper, woven plastic bags.

- The operator can periodically cut the compacted bags.

- The compaction rate can be adjusted with chain settings.

- The machine has a PE tube to prevent friction.

- The empty bag compactor is made of epoxy-painted steel.

Request Technical Information

Request Technical Information

To receive more detailed technical information about the product, please fill out the form below.