- T-MAX Products

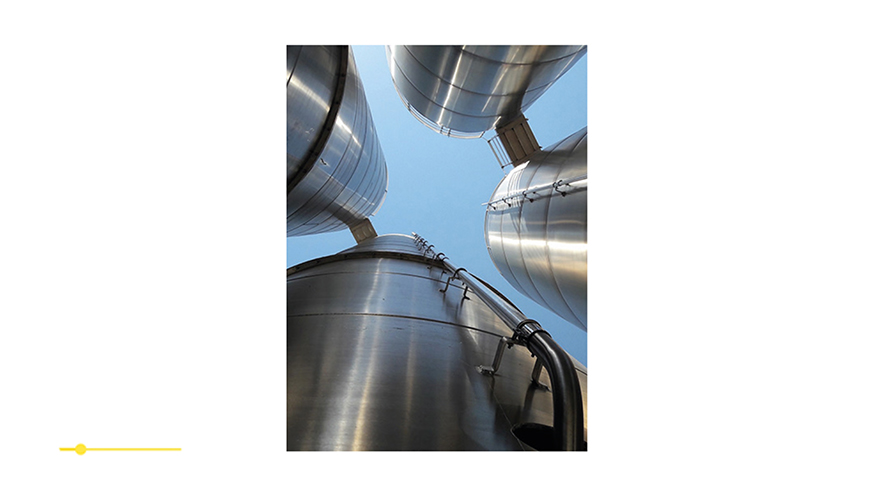

- Aluminum Raw Material Silos

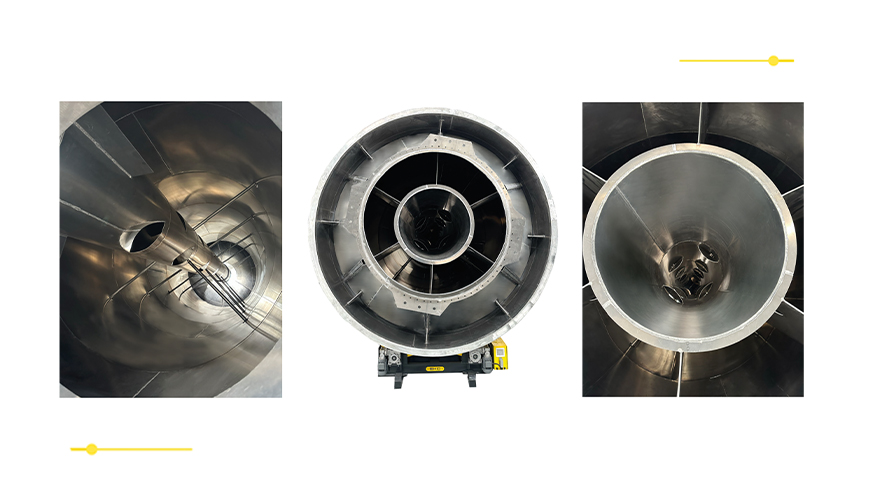

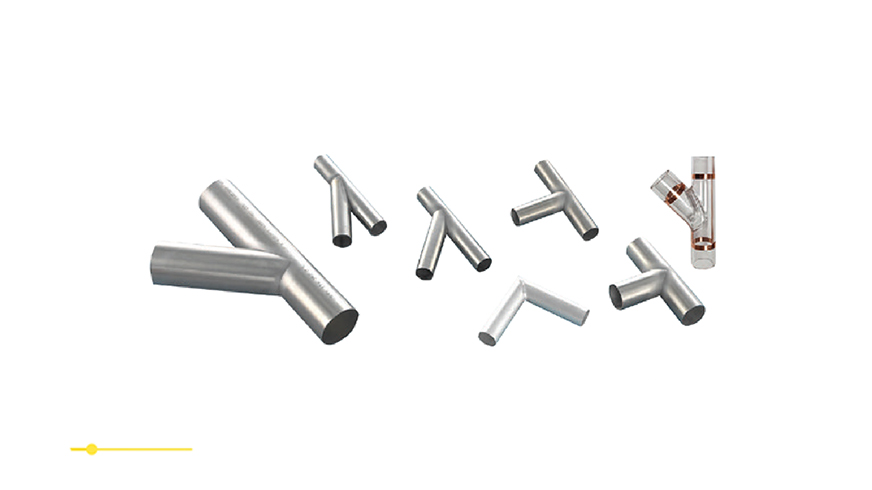

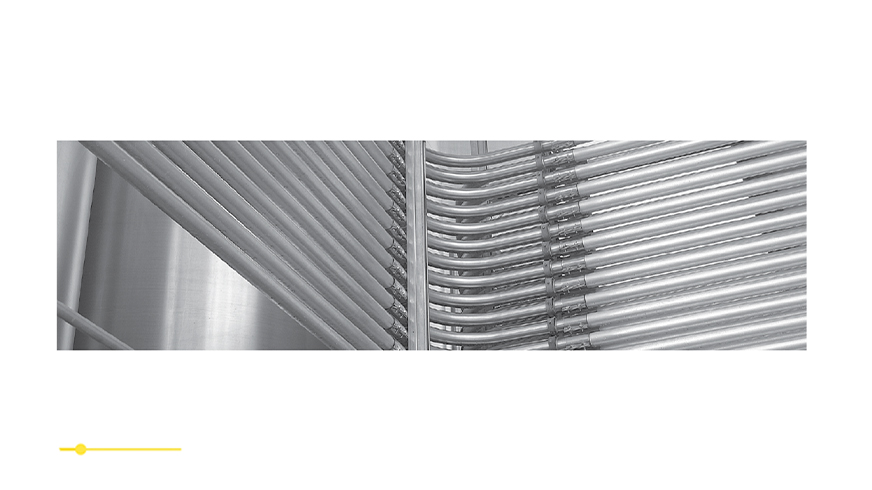

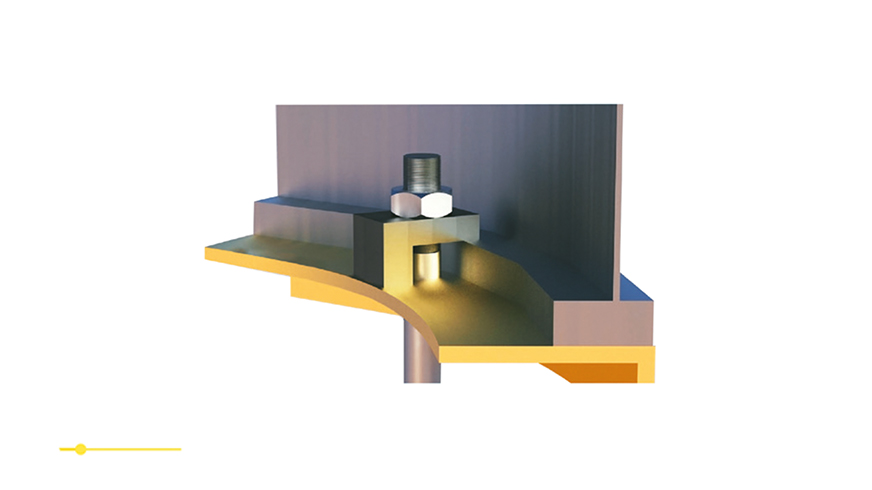

- Central Pipe Type Gravity Mixer

Central Pipe Type Aluminyum Raw Material Silo Gravity Mixer

The pipe placed in the center of the silo has various inlet openings. Due to the special material acquisition areas, the product flows from different regions, benefiting from gravity forces, ensuring homogeneous mixing. Different geometries of inlet openings on the pipes create different flow rates according to the raw material. This ensures the homogeneous mixing of the raw material.

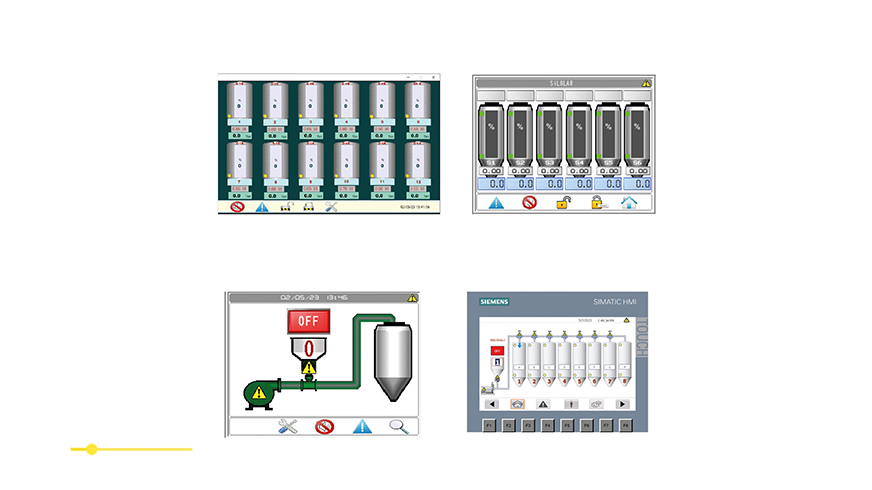

FEATURES

- Standard silo measurement and control panels that provide control for 4-6-8-10 silos are available.

- Raw material tracking can be easily done with the advanced screen.

- Screen options are available in 3.5, 5.7, and 10-inch sizes.

- The audible and visual warning system quickly alerts the operating personnel.

- The Ethernet port facilitates access to the operating database.

- Remote access is possible via the PC interface program.

- ERP integration further optimizes business processes.

- The Industry 4.0 compatible software infrastructure supports future use of the system.

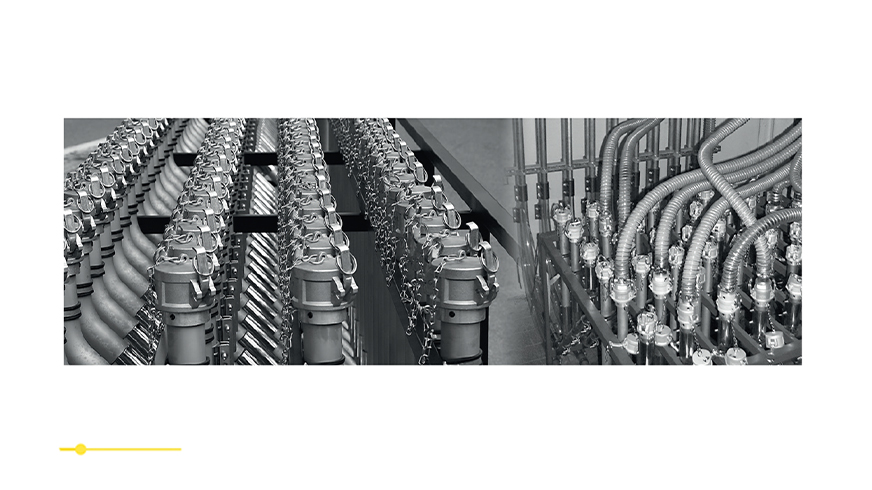

- Compatibility with silobas, bag cutting, and container units provides flexibility.

- Optionally, RFID can be used for error prevention in silo filling lines.

- POKA-YOKE (Error Prevention) is ensured by the safety mechanical connection.

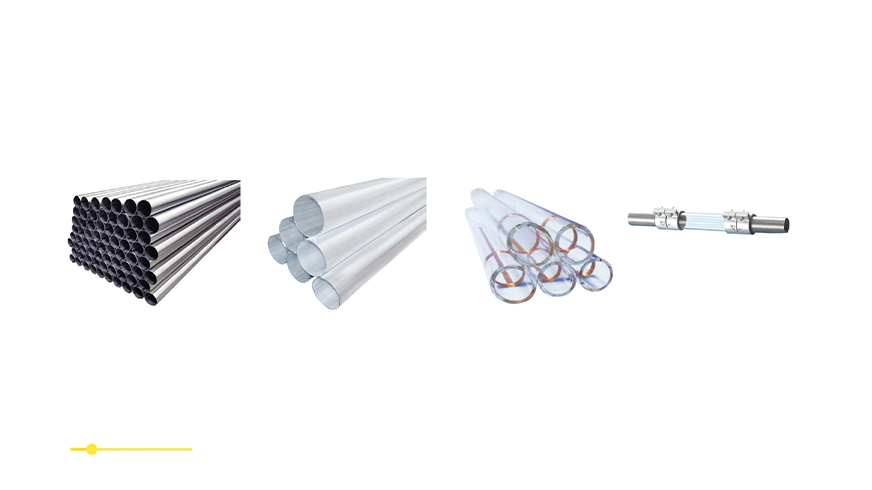

SENSOR TECHNOLOGY

- We can use the measurement values obtained by the sensors in various ways.

- These values are not only displayed on the screen but also offered through different programs and analysis devices for use in complex process analyses over Ethernet.

- For level measurement, we use sensors with radar, load cell, or YO-YO techniques.

- We recommend sensors that are functional and suitable for the features and silo volumes.

- We also enable the transmission of measurement values over radio link.

MINIMUM AND MAXIMUM LEVEL SENSORS

FEATURES

- Real-time or continuous measurement capability is available.

- Parameter entry is very easy using handheld terminals.

- The contactless measurement technique ensures that the device does not wear out and does not require maintenance.

- It is not affected by external factors.

- Calibration is easy and hassle-free.

WEIGHT MEASUREMENT SYSTEM

- The raw materials inside the silos are weighed and measured using load cells.

Request Technical Information

Request Technical Information

To receive more detailed technical information about the product, please fill out the form below.