- T-MAX Products

- Bagomax Automatic Bag Opening / Emptying

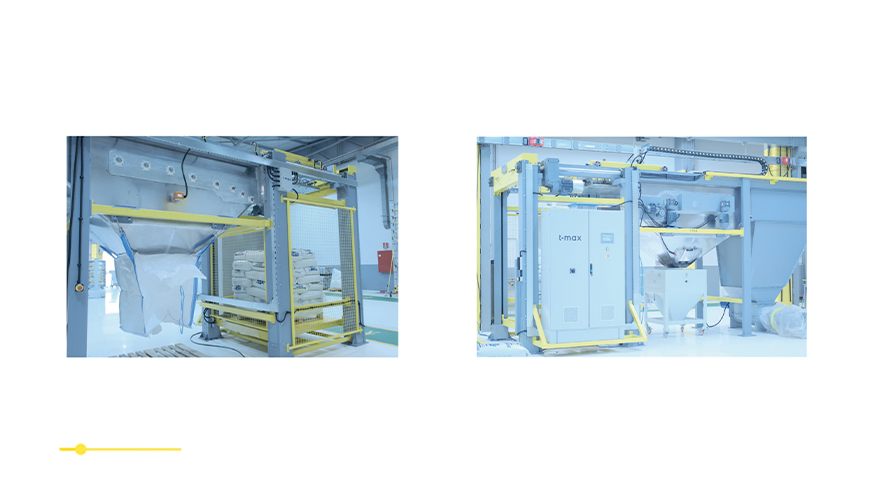

- Bag Opening and Emptying Machine

Bagomax Fully Automatic Bag Openning Machine

ADVANTAGES

- Offers expandability: You can add a bag compactor and a pallet stacker.

- Complete process control can be applied in a complex control system.

- Provides flexibility. (additional options available.)

- Offers powerful application.

- Has separate fixed movements.

- The electric lifting performs vertical movement, and the shuttle performs horizontal movement.

- Ideal for high-capacity factories.

- Reduces labor costs.

- Ensures full compliance with occupational safety standards.

- Empties all granules in the bag.

- Reduces the risk of raw materials and foreign substances escaping.

- Can be seamlessly integrated into central systems.

- Compatible with existing silos or filling units.

- Offers a high investment return ratio.

AVANTAJLAR

- Genişletilebilirlik imkanı sunar: Bir torba sıkıştırıcı ve bir palet istifleyici ekleyebilirsiniz.

- Tam proses kontrolü ile karmaşık kontrol sisteminde uygulanabilir.

- Esneklik sağlar. (ek seçenekler mevcuttur.)

- Güçlü uygulama sunar.

- Ayrılmış sabit hareketleri vardır.

- Elektrikli kaldırma dikey hareketi ve mekik yatay hareketleri yürütür.

- Yüksek kapasiteli fabrikalar için idealdir.

- İşçilik maliyetlerini düşürür.

- İş güvenliği standartlarına tam uyumluluk sağlar.

- Torbadaki granüllerin tamamını boşaltır.

- Ham maddelerin ve yabancı maddelerin kaçma riskini azaltır.

- Merkezi sistemlere sorunsuz bir şekilde entegre olabilir.

- Mevcut silolar veya silo doldurma üniteleri ile uyumludur.

- Yüksek yatırım rasyonu sunar.

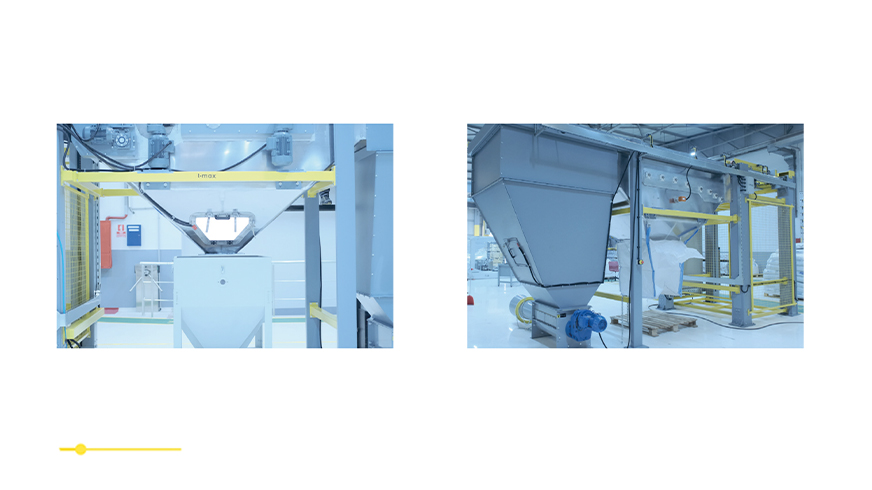

A fully automatic bag opening and emptying machine can easily open and automatically empty 25 kg plastic, paper, or jute bags into a collection hopper.

- Filled bags can be placed on the machine automatically or manually along with the pallet.

- The machine’s capacity can operate up to 15 tons per hour, depending on the selected application and the product to be processed.

OPERATING PRINCIPLE:

- After placing a loaded pallet on the machine, the movable hooks lift the pallet.

- Integrated hooks take the top layer of the pallet and then transfer it over the rotary blades to the collection hopper.

- These rotary blades cut the bags, causing the granules to fall into the hopper.

- The specially designed shaking method ensures that the bag is completely emptied.

- The emptying rate is higher than 99.98%.

- After the bags are emptied, the movable hooks automatically drop the empty bags into a collection hopper.

- With an additional equipment called the “Bag Compactor,” the empty bags can be transferred to a bag compactor or baling machine for disposal.

- The granules in the collection hopper are pneumatically transported to external silos or desired locations.

- The fully independent bag opening and emptying machine is controlled by a Siemens S7 PLC.

ALTERNATIVE DESIGNS AND EXTRA OPTIONS

XL Unit:

- Designed to unload granules into containers, big bags, octabins, or truck loads.

- Automatic Cleaning: This machine can automatically clean itself after completing a batch process and quickly become ready for processing a different product.

- The machine’s automatic pallet transport feature facilitates the easy movement of pallets in and out.

- An integrated empty pallet stacker is available for stacking empty pallets.

- For empty bags, an integrated bag compactor or baling machine options are available.

Request Technical Information

Request Technical Information

To receive more detailed technical information about the product, please fill out the form below.