- T-MAX Products

- Cooling and Heating Units

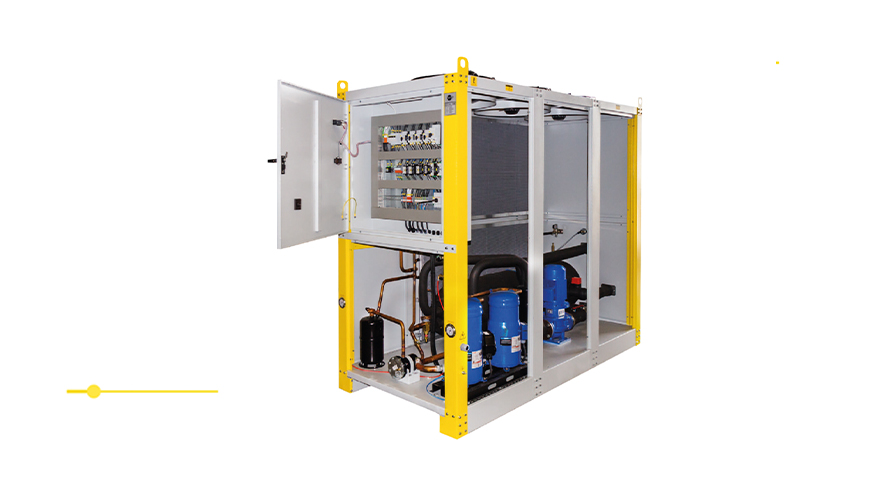

- Chillmax Chiller Units

CHILLMAX CHILLER

CHILLMAX CHILLER

Under the guarantee of Tepro Machine, T-MAX products provide customers with high-quality and reliable solutions. As a leading organization, we carefully select our products based on our extensive experience and expertise. Products offered under the T-MAX brand are chosen with the philosophy of “best quality at affordable prices,” providing efficiency-enhancing benefits and flexible usage advantages.

MODULAR DESIGN

T-MAX cooling systems are designed to work independently or in groups with other T-MAX or different brand chillers, offering compatibility and flexibility in operation.

MAINTENANCE EASE

The easy accessibility of all parts ensures that service can be provided quickly and effectively.

Panels made of galvanized steel are designed for easy disassembly and portable use.

These panels are coated with 60 microns of epoxy paint, providing both a stylish appearance and durability.

MAIN BODY

The main body is made of galvanized steel and coated with epoxy paint, at least 60 microns thick.

This ensures that t-max chillers are effectively protected, maintaining their appearance and value for years.

The advanced main body design ensures minimal energy consumption and high efficiency.

Designed in compliance with CE standards.

Offered to customers with a competitive price advantage.

Its modular design allows for easy installation and replacement.

Optionally available with stainless steel pump.

Operates at minimum noise levels thanks to its very quiet condenser.

Provides high efficiency with scroll or screw-type refrigeration compressor.

Optionally, electronic expansion valve can be used for precise control.

Ensures stable operation by continuous monitoring of process fluid.

Cooling capacity is continuously adjusted automatically.

Draws low current and saves energy upon activation.

User-friendly with easy and economical maintenance features.

Advantage of having stocked products and spare parts for immediate delivery.

Provides technical support service 24/7.

These features highlight the robustness, efficiency, and user-friendly nature of t-max chillers, ensuring reliable performance in industrial cooling applications.

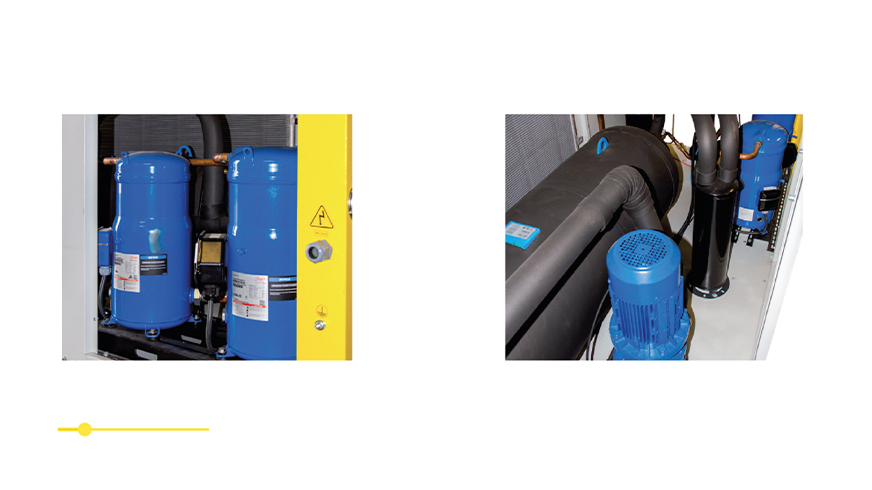

COMPRESSOR

The circulation of the refrigerant fluid in the system is ensured by a robust scroll compressor resistant to overload or, for larger capacities, a screw-type compressor.

Depending on the model, it has a structure where independent refrigerant circuits can be connected or twin compressors can operate in and out according to the desired temperature.

This ensures both maximum efficiency and simultaneous aging.

EVAPORATOR

The shell and tube evaporators used can automatically self-clean through the maximum water turbulence method.

Operating on the principle of dry expansion, the system separates water and gas, and tank surfaces are insulated with protective insulation against unwanted heat transfers.

In this “Counter-Flow” system, water and gas flow in opposite directions to achieve maximum cooling efficiency.

Maximum heat transfer has been achieved.

Unwanted heat transfers have been prevented.

High efficiency is achieved thanks to compressors operating at low gas pressures.

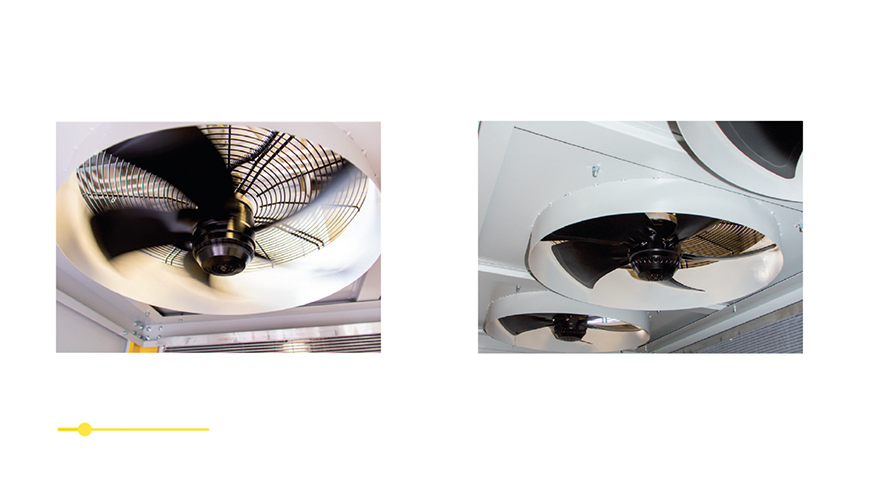

FANS

t-max cooling units are manufactured using carefully selected fan brands from leading fan manufacturers.

WATER COOLING CIRCUIT

The cooling circuit consists of copper pipes and includes the following components:

For all models:

External balancing (optional with electronic valve)

Expansion valve

Valve on the liquid line

Dryer filter

Solenoid valve

Liquid and moisture indicators

Crankcase heater

High and low pressure switches

Oil level indicator

Safety valve on the compressor

High pressure and low pressure gauges

WATER CIRCUIT

The water system includes the following components for all models:

Manifolds and connecting parts

Evaporator

Flow meter

Pressure gauge

Pump accessories

ELECTRICAL PANEL

The control panel is mounted on top of the unit and is protected with IP55 classification.

The door lock is connected to the main switch according to European standards.

The wiring is compliant with IEC standards.

The electrical panel, according to IEC 947, includes magnetic thermal protection for fuses, compressors, and fans.

The circuit start of compressors is protected by auxiliary power fuses for screw (optionally soft start or star-delta) and scroll compressors.

CONTROL

The cooling process is controlled by a microprocessor.

It is electronically managed using a control system loaded with Carel or Dixell software.

Programming is directly done from the screen using a data processing input that displays nominal values and error conditions.

Visual and audible alarm features are also available.

Parameters are retained in the memory of the control system in case of a power outage.

MICROPROCESSOR

All functions are controlled by and settings are made through the microprocessor.

Values and parameters required for operation can be entered directly through the microprocessor.

Each chip has the capacity to control 4 compressors.

Various functions in the system are equipped with audible and visual alarm buttons for continuous monitoring.

System memory is preserved in case of power failure.

Set points can be changed and adjustments can be made via the display.

FEATURES

•Readable input and output temperature indicators.

•Adjustable alarm settings for identification and visual alerts.

•Optional dual pump and alternative operation control.

•Optional modular control valve provides “free cooling” capability.

•Current switch delay during startup.

•Compressor(s) have runtime counter feature.

•Direction of rotation of compressors can be controlled.

•Pump function is provided with soft shutdown.

•Electronic thermostat with anti-freeze feature.

•Remote stop-start feature available.

•Manual operation is possible.

•Manual reset capability.

Alarms include:

•Audible alerts for high and low pressure, oil, and overheating conditions.

•Alerts for compressor overload.

•Fans operate based on freeze flow switch during overload and overheating conditions.

•Alerts for EPROM error.

To receive more detailed technical information about the product, please fill out the form below.