- T-MAX Products

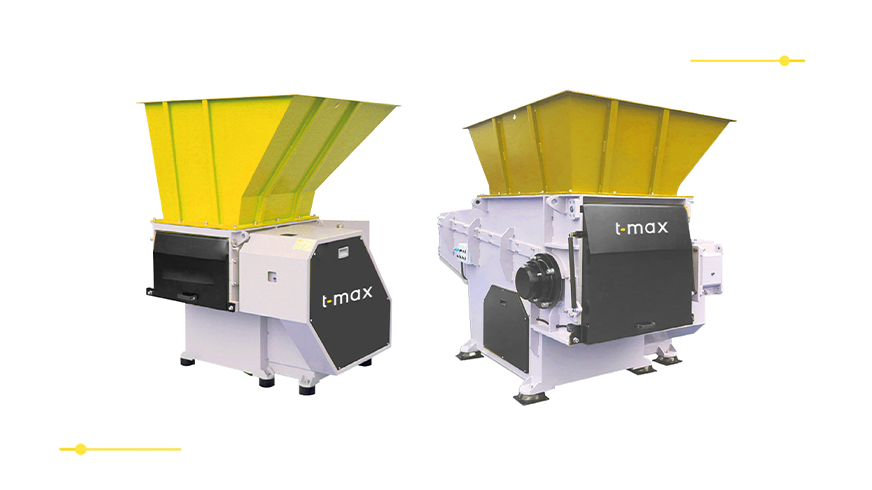

- Shredders – Crushing Machines

- P Series Single Shaft Shredder

P Series Single Shaft Plastic Products Shredder - Grinder Machine

FEATURES

The P series single shaft shredders are used for shredding and recycling small to medium-sized materials in various industries.

This machine is designed with low speed, high torque, and a compact structure for uniform shredding of plastic blocks and parts.

It can maintain stability and reliability in challenging environments.

It is used for products such as plastic blocks, plastic pipes, plastic sheets, PE film, sacks, PET materials, aluminum, copper, wire, cables, and more.

The moving blades are made of DC53, while the fixed blades are made of D2 steel.

An additional pusher is optional for hollow massive materials.

The automatic reverse system redirects the shredder rotors in cases of motor overload and material jamming.

The main electrical components are from reliable brands like Siemens and Schneider.

Quick changeover is facilitated by easy access to the rotor and screen.

Multiple screen models are available and can be easily replaced.

The guide rail and pusher are interchangeable, allowing for smooth pushing and pulling to keep the crushing chamber fully enclosed.

The plastic shredder (single shaft) consists of main shaft, blades, fixed blades, box, feeding system, pushing system, and power system components.

It controls the output size by using the interaction between the moving and fixed blades to shred, cut, and compress the material into smaller sizes.

It is typically used for primary crushing of various solid plastic wastes, processing materials into smaller sizes in one go.

It features controllable discharge particle size, broad material applicability, and high efficiency properties.

EQUIPMENT FEATURES

The moving blade is made of DC53 material, while the fixed blade is made of D2 material.

A conveyor for hollow and large-volume materials can be selected.

The overload feeding function prevents serious overloading and ensures safe operation of the device.

International brands like Siemens and Schneider are used for main electrical control components.

Blade changes can be performed quickly and effectively using split combination technology.

The moving blades are interchangeable and have sharp edges.

The screen diameter can be changed over a wide range.

To receive more detailed technical information about the product, please fill out the form below.