- T-MAX Products

- Thermoregulator Units

- Dualmax Thermoregulator Units

Dualmax Series Heating & Cooling Thermoregulator TCU Units For Plastic Processing

t-max has achieved heating and cooling processes in molds with its new Dualmax series through a single device and data integration.

FLEXIBLE USE IN PLASTIC PROCESSES:

It is a water-cooled unit equipped with integrated standard, high-pressure, or booster pumps, offering single or dual-zone heating and cooling functions in one device.

t-max’s new series helps optimize cycle times in processes while occupying minimal space and operating seamlessly as part of the business.

High-pressure and high-flow pumps ensure precise control of mold temperatures with high control accuracy through the heating system.

The optional “Free Cooling Valve” operates as needed to provide energy savings for economical operation.

It offers a wide range of models and capacities to meet various needs.

With a touchscreen control panel, you can monitor the device’s every move and temperature in real-time on the screen.

It allows continuous monitoring of set and instantaneous values, contributing significantly to minimizing cycle times.

Temperature control units offer options ranging from 6 to 48 kW heating power and up to 195 kW cooling capacity.

They also provide two options for pump pressure and flow:

SB = Standard pressure and high flow

HB = High pressure and high flow pumps

The use of high-quality components tested under the most challenging conditions ensures that Temperature Control Units operate at maximum efficiency for many years, even under the toughest operating conditions.

ADVANTAGES

It provides synchronization with the machines and processes to ensure seamless adaptation.

Contributes to reducing cycle times by up to 50%.

Utilizes smart energy consumption strategies.

Enables energy savings through Free Cooling Valve integration.

Saves time with mold water drainage kit usage.

Enhances efficiency with visualization and communication interface software.

Allows monitoring of temperature, flow, and pressure at input and output points directly from the screen.

MOLD TEMPERATURE CONTROL

Mold temperatures directly impact cycle times and product quality.

Temperature control is crucial and requires high precision.

OPTIMUM PRODUCTION CAPACITY

Increasing production capacity contributes to eliminating waste and idle times.

It ensures better product quality, improved surface appearance, and tensile strength.

Contributes to reducing production costs.

Provides low waste and energy costs.

PROCESS GAINS

Provides high efficiency and excellent repeatability.

Enables optimal cooling conditions and stability.

Offers set values independent of operating conditions.

Optionally allows for pressure-flow and temperature control of two separate processes.

Ensures precise control over process temperatures.

Provides continuous and controlled cooling values.

Achieves continuous and efficient cooling with minimal temperature differences in mold heating.

Offers reliable quality and device structure.

Provides permanent solutions to known classical cooling problems (sweating, surface and visual defects, dimensional issues).

Ensures strong integration between machine, operator, and device.

USER BENEFITS

Enables low energy consumption and quick startup.

Contributes to low energy consumption with high-efficiency pumps.

Ensures high productivity with low heat loss during production.

Eliminates waiting times and ensures rapid mold changes.

Advantageous with low maintenance costs.

Due to 80% less cooling gas content compared to central chillers, it has minimal environmental impact.

Independent free cooling valve in each device ensures high energy savings.

FEATURES

Provides a “7” color touchscreen control panel.

Facilitates ease of use with multiple language options.

Includes a help menu with usage and troubleshooting guidelines.

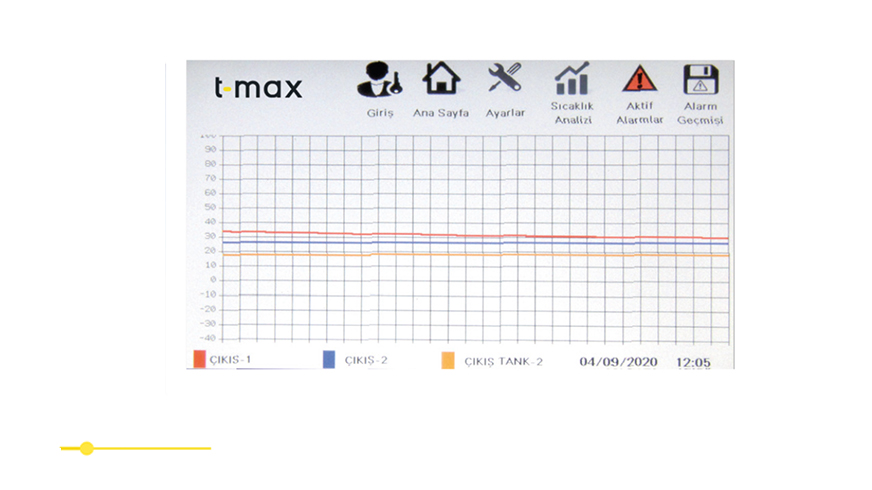

Graphically displays symptoms of main operating variables.

Makes the operation principles understandable with a comprehensive view of all water and cooling parameters.

Displays percentage readings and screen reflections of compressor usage.

Enables readable output temperature values for each zone.

Enables readable input and return pressure values for each zone.

Optionally equipped with flow indicators for each zone.

Optionally calculates pressure and flow differentials.

Allows selection of metric or imperial values on the standard user panel.

Optional automatic free cooling mode is available.

Optional remote start-stop function is provided.

Provides protection against high/low pressure differentials.

Sensor connections are protected against interruption and short circuits.

Includes anti-freeze protection feature.

Graphically displays deviation curve from set values.

Long-term deviation from set point is indicated by a continuous signal.

The control panel can store 1000 records on an SD card for 50 alarms.

Automatic air discharge and water filling feature included.

Provides individual motorized cooling control for each zone.

Includes a dedicated process pump for each zone.

High-efficiency circulation pump is used.

Filtration is performed at the water inlet.

Filtration is performed at the return process water inlet.

Includes a bypass valve suitable for standard pressure settings.

Audible alarm feature is included.

Equipped with heavy-duty transport wheels suitable for harsh conditions.

DIGITAL CONTROL AND SAMPLE SCREEN VISUALS

MAIN USER INTERFACE

“All unit variables, including water regime and cooling regime temperatures and pressures, are displayed on the screen.

Screen colors and colored indicators make compressors, heated pumps, free cooling valves, and 3-way valves with active or inactive function indicators showing performance in internal or external set values clear.”

MAIN USER SCREEN “CHILLER COOLING SECTION” PAGE

“All variable values such as cooling temperatures and pressures are displayed on the screen. Additionally, adjacent pages include values for secondary cooling and super rapid heating.”

MAIN USER “ZONE 1 AND ZONE 2 SELECTION” PAGE

“All pump values, flow and return pressures, calculated instantaneous and set flow rates (including optional flow rates), pump and heating kW values are displayed with indicators.

Pump performances and temperatures can also be seen with graphical indicators.”

CHILLER PERFORMANCE PAGE

The performance of the chiller is graphically represented over a 60-minute time period based on the set point. In this graphical representation, compressor loads are also displayed. Additionally, cooling capacity, power consumption, and COP values are shown as indicators on the screen.

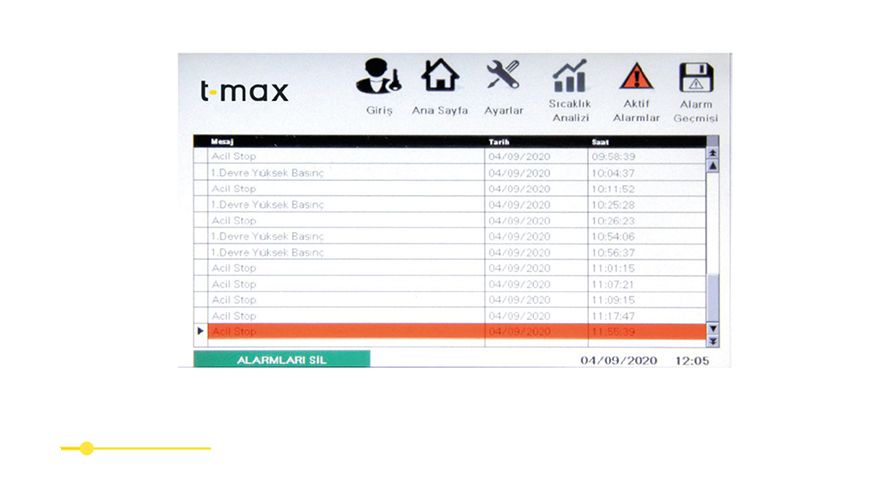

HISTORY OF ALARMS

There are additional information indicators or delay settings available for each alarm condition.

All alarm descriptions, along with explanations and fault resolution suggestions in the user’s language, are listed in the alarm history.

COOLING COMPONENTS

Scroll compressors offer high efficiency and very low noise levels.

Shell & Tube evaporators are free from classic issues such as clogging or exchanger leaks.

The condenser pressure control operates at a constant pressure controlled by a pressure valve.

The dual alarm system provides bidirectional high-pressure gas control both mechanically and through software.

Ecological refrigerant gases comply with European standards and directives.

INTERNAL CONNECTIONS AND COMPONENTS

Designed to provide stable pressure and flow to both the process and the evaporator.

Can utilize single or dual process pumps designed with specially engineered, high-flow, and durable seals.

Wide range of pump flow rates available, ranging from 20 to 450 m3/h.

The circulation pump ensures a consistent water regime in the evaporator.

Efficient heating elements are employed.

The device is equipped with a safety thermostat.

Modulation valves are used for each zone to provide proportional and precise temperature control.

Stainless steel piping and connections are used throughout the device.

Includes an insulated stainless steel expansion tank.

OPTIONS AND ACCESSORIES

Serial Connection: Easily integrated into the central control panel through interface protocols and various serial connections.

Audible Alarm: In addition to optional audible alarms, visual alarms can also be integrated upon request.

Separate and Independent Operation:

Custom device models are designed to operate completely independently, suitable for specific applications and processes. For these models, please contact our sales department.

Tower Kit: We offer a tower kit to prevent contamination risks and mitigate pollution that may occur in the condenser when the device is fed from an open tower or cooling unit.

Isolation Kit: Our isolation kit, which can be used with flow meters and ambient temperature indicators, is preferred in situations where lower temperatures are required.

ELECTRICAL AND CONTROL EQUIPMENT

Equipped with an electric control panel with a lockable safety switch.

Electrical circuit protections are available for compressors and pumps.

Provides precise control through microprocessor control.

The size of the touchscreen color display is 7 inches.

Visualization can be performed using optional interface software that allows communication with central control or process machines.

Cooling and water circulation can be fully controlled from the screen with pressure and temperature sensors.

Selected language, alarms, errors, and other parameters can be displayed with visual functions.

The screen includes language selection, descriptions of solutions and intervention steps for alarms and faults.

Operates with +10C precision and includes alarm features thanks to proportional integrated smart control.

Mold water filling and draining procedures can be performed via the control panel.

Standard audible alarm is available.

Visual alarm connection point is available for installation.

CHASSIS:

Main body is coated with epoxy paint.

Side panels are removable for easy access.

Compact design with sturdy wheels for easy mobility.

To receive more detailed technical information about the product, please fill out the form below.