Weighmax Raw Material Vacuum Feeding & Weighing Containers

please contact us at

+90 216 709 26 00.

- OUR OTHER PRODUCTS

- The SWH series weighing station with vacuum feeding unit enables the homogenization of multiple or single raw materials for both vertical and horizontal mixers. It also facilitates precise and easy measurement feeding processes in hoppers before storage or processing.

FEATURES

•High operational safety is ensured through years of experience and fully advanced technology.

•Material scattering and handling issues are eliminated within the operation, enhancing productivity.

•Automatic feeding to vertical or horizontal mixers, bins, or big bags is performed with high precision.

•Various feeding options are available with single or multiple lines.

•Easy and quick cleaning saves time during the production process.

•Mixtures measurable in units like kg, hour, shift, etc., provide reports on blends.

•High weighing and dosing precision ensures consistent product quality.

•Quick cleaning with large cleaning lids is facilitated.

•Provides maximum flexibility to operations.

•Achieves consistent quality in production, thereby increasing customer satisfaction.

•Enhances efficiency within operations through rapid recipe changes.

•Advanced control unit ensures accurate production coordination.

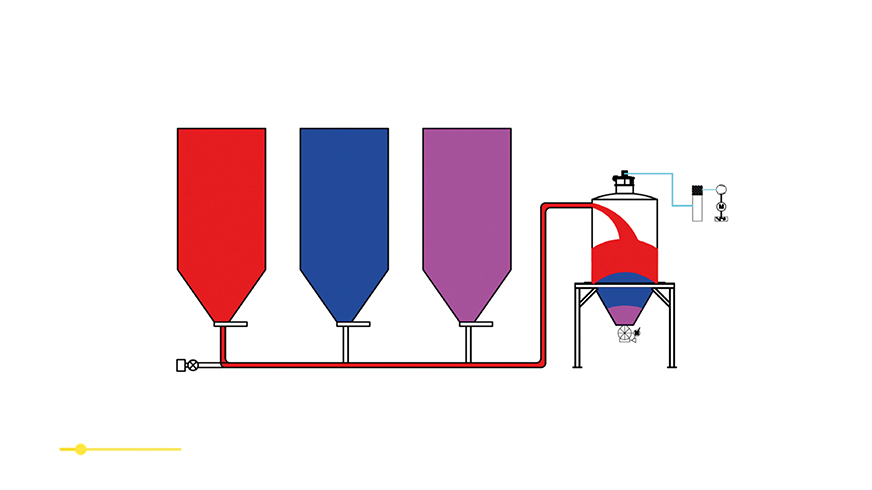

SINGLE RAW MATERIAL SYSTEM

With the single-line system, easy access to the weighing hopper is facilitated from all product feeding points.

Products from different feeding points such as mixer bunkers, big bag discharge stations, open or closed silos are accurately weighed and measured with precision.

Variations in distances between different transfer points are compensated for with measurement and weighing controls.

This feature ensures stable operation of the unit and enhances its accuracy.

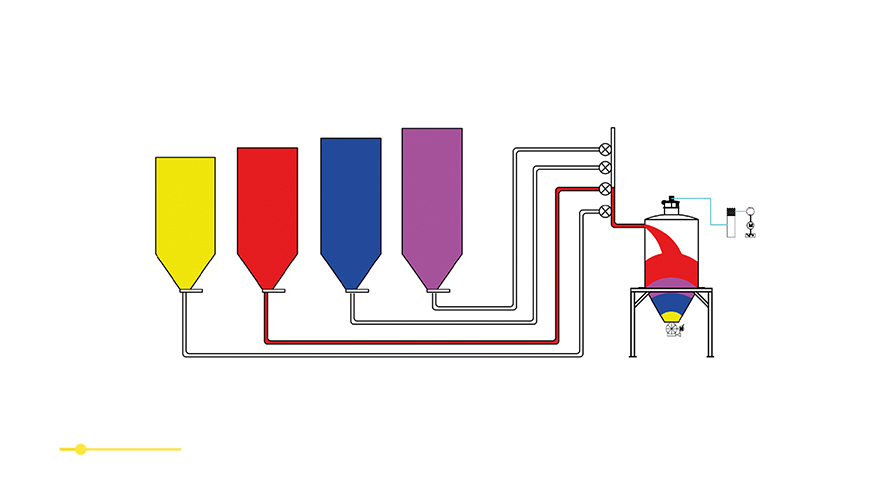

MULTIPLE RAW MATERIAL FEED SYSTEM

In a multi-line feeding system, it independently feeds from different points according to the recipe set in the control unit.

After reaching the set value from each feeding phase, it continues to feed the next raw material.

The unit’s cleaning function ensures that line cleaning is performed after each cycle, guaranteeing maximum weighing accuracy.

The system offers more flexible operation compared to single-pipe systems.

CENTRAL WEIGHING SYSTEM AND HOPPER

A central weighing system and hopper are available for multiple input and discharge points.

Feeding into the system is done through a central vacuum pump.

This allows transitions and line cleaning processes to be conducted rapidly and in a controlled manner.

This feature ensures extremely high weighing accuracy.

By combining the advantages of a vacuum system and weighing functionality, businesses benefit from significant cost savings, reduced labor, and production advantages with precise recipes.

To receive more detailed technical information about the product, please fill out the form below.

To access our product digital catalog, please fill out the form below.